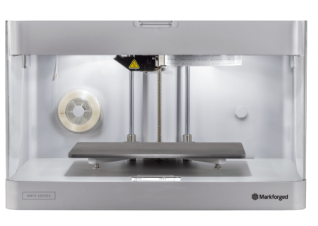

Onyx Pro

Markforged Onyx Pro is a 3D Printer designed for printing 3D parts with the additional option of adding reinforcing fibers of fiberglass, this makes it Capable of 3D printing Fiberglass-reinforced parts 10x stronger than ABS. The Markforged Fiberglass is a continuous fiber designed to reinforce Onyx material. The 3D printed composite parts containing fiberglass offers ten times stronger and stiffer than plastic. Additional to this Competitive pricing makes it an ideal choice for most users.

Hardware

-

Printing Process

Continuous Fiber Reinforcement (CFR) -

Z Layer Resolution

100 μm - 200 μm -

Printing Media

Composite Base Filaments, Continuous Fibers

-

Internal Part Geometry

Closed Cell Infill with Continuous Fiber Reinforcement -

Print Bed

Precision Ground Composite -

Build Volume

320 mm x 132 mm x 154 mm

System Details

The Onyx Pro is professionally-engineered using high-quality components and advanced cloud-based 3D printing software Eiger for smooth operations. The Onyx Pro features two extruders. The first printhead is designed to create parts with the Onyx chopped carbon fiber filament and the other printhead is exclusively designed for continuous fiberglass to reinforce the 3D printed part. The Eiger delivered with Markforged Onyx Pro is an easy to use software designed to reduce the user's workload as much as possible. It also provides good connectivity via Wi-Fi, Ethernet, or USB stick which gives the user's precise control over printing jobs.

Materials

- Onyx™

- Fiberglass

- Precise PLA

- Smooth TPU 95A

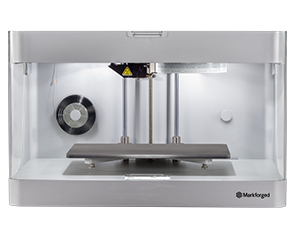

Mark Two

The Mark Two is a powerful 3D printer that can create strong, lightweight components. Markforged is the first company in the world to introduce a 3D printer capable of embedding continuous strand of carbon fiber, Kevlar®, and fiberglass into high-quality nylon. This allows engineers and manufacturers to manufacture parts with the strength of aluminum. It's a desktop printer, so it is small and easy to use.

Hardware

-

Printing Process

Continuous Fiber Reinforcement (CFR) -

Z Layer Resolution

100 μm - 200 μm -

Printing Media

Composite Base Filaments, Continuous Fibers -

Power

100-240VAC, 150W (2A peak)

-

Internal Part Geometry

Closed Cell Infill with Continuous Fiber Reinforcement -

Print Bed

Precision Ground Composite -

Build Volume

320 x 132 x 154 mm (12.6 x 5.2 x 6 in) -

Weight

16 kg (35 lbs)

System Details

The Markforged Mark Two is professionally-engineered using high-quality components and advanced cloud-based print software Eiger for smooth operations. The Mark Two features two extruders and uses Composite Filament Fabrication (CFF) 3D printing technology. The first printhead is designed to create nylon or onyx parts, and the other one is a revolutionary new composite printhead that continuously adds fiber composite material to reinforce your print. Mark Two allows users to produce parts with greater stiffness and strength up to twice as strong as ABS. The parts printed on this carbon fiber 3D printer can tolerate the heat up to approx 145° C. With Mark Two, you can also print white nylon, a non-abrasive engineering thermoplastic, ideal for non-scratching parts or work holding, and printed parts for repeated handling.

Materials

- Onyx

- Nylon

- Carbon Fiber

- Fiberglass

- HSHT Fiberglass

- Smooth TPU 95A

- Aramid Fiber (Kevlar®)

- Precise PLA

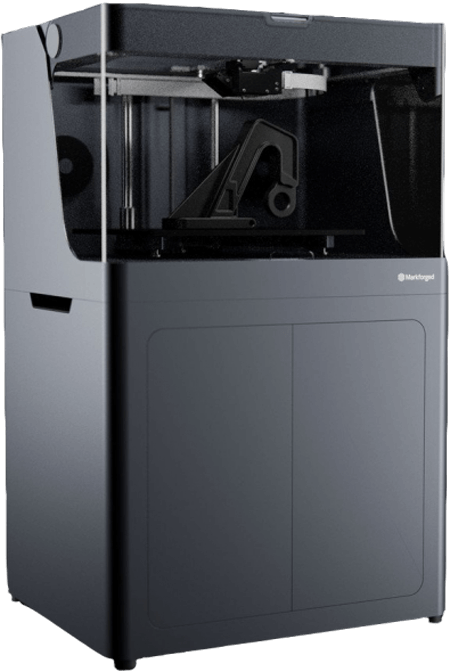

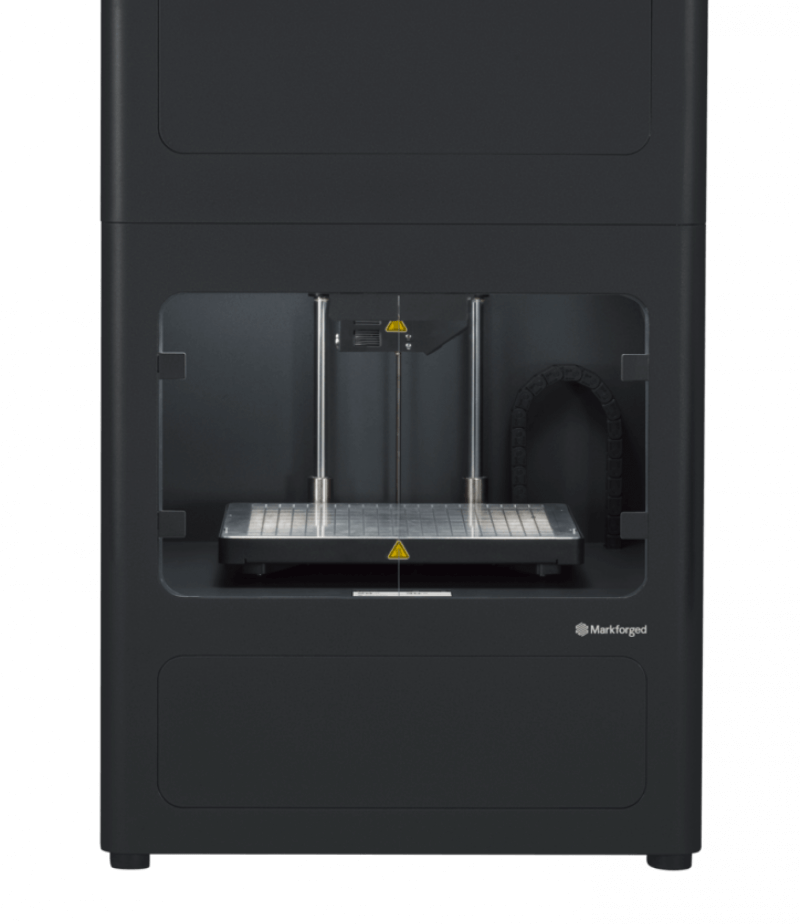

X7

The Markforged X7 offers exceptional capabilities for printing faster and cheaper industrial parts such as jigs & fixtures, components, prototypes, robotics, custom-fit parts, end-use, functional parts, and even load-bearing applications that require real force. It can 3d print high-quality parts in Onyx, providing parts with incredible stiffness, high-temperature resistance, and smooth surface finish. This Composite 3D printer reinforces the object with continuous composites such as Carbon Fiber, making the printed parts as strong as metal!

Hardware

-

Printing Process

Continuous Fiber Reinforcement (CFR) -

Z Layer Resolution

50 μm - 250 μm -

Printing Media

Composite Base Filaments, Continuous Fibers -

Power

100-240VAC, 150W (2A peak)

-

Internal Part Geometry

Closed Cell Infill with Continuous Fiber Reinforcement -

Print Bed

Precision Ground Composite -

Build Volume

330 x 270 x 200 mm (13 x 10.6 x 7.9 in) -

Weight

48 kg (106 lbs)

System Details

The Markforged X7 3D printer offers many features including advance cloud-based print software Eiger – an easy to use software designed to reduce the user’s workload as much as possible. It also provides good connectivity via Wi-Fi, Ethernet, or USB stick which gives the user’s precise control over printing jobs. The X7 has a default Z-layer resolution of 100 microns with the ability to print at 50 microns, producing an excellent print quality. The dual nozzle print system of Markforged X7 provides an option to include fiber in Fiberglass and Kevlar using the Composite Filament Fabrication (CFF) process. This composite 3D printer also has a Turbo Print – a new feature from Markforged that doubles the system’s print speed without jeopardizing surface quality. This feature enables customers to quickly replace parts, increase production volume, and provides a better return on investment.

Materials

- Onyx

- Onyx ESD

- Onyx FR

- Nylon

- Carbon Fiber

- Fiberglass

- Aramid Fiber (Kevlar®)

- HSHT Fiberglass

- Carbon Fiber FR

- Smooth TPU 95A

- Precise PLA

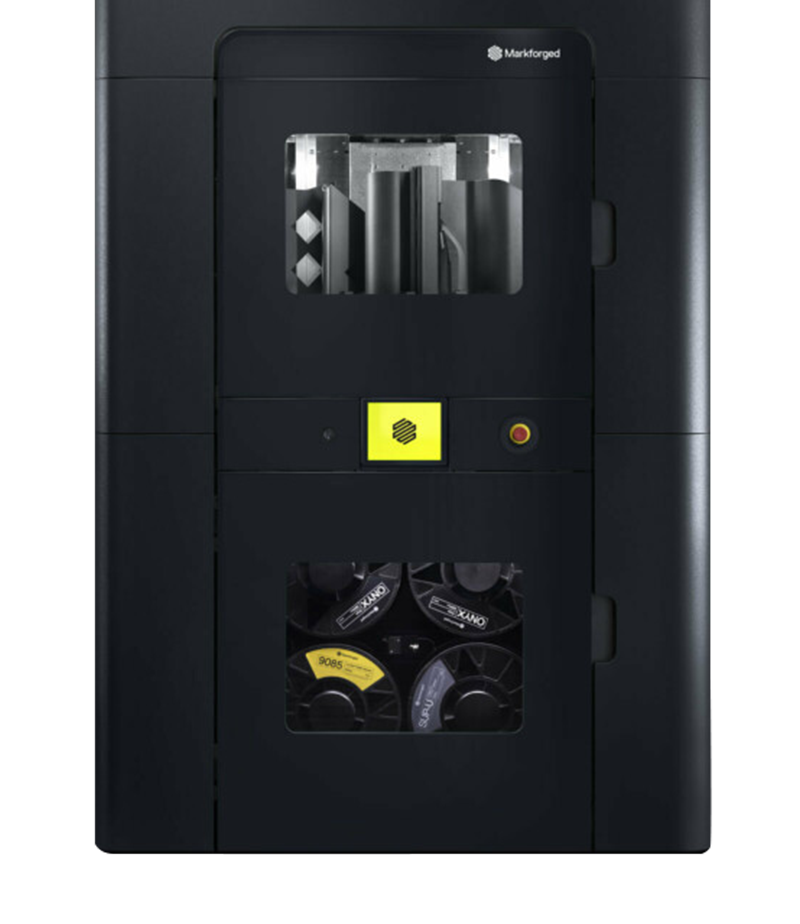

FX20

The FX20 is transforming the Digital Forge into a next generation additive manufacturing platform, capable of printing high-temperature thermoplastics reinforced with continuous fiber at the click of a button. By printing high-strength, more accurate and higher performance parts, the FX20 meets the needs of even the most demanding and regulated industries, such as aerospace, defense, automotive and oil & gas.

Hardware

-

Printing Process

Fused Filament Fabrication, Continuous Fiber Reinforcement -

Z Layer Resolution

50 μm - 250 μm -

Printing Media

Polymer Filament, Continuous Fibers

-

Internal Part Geometry

Closed Cell Infill with Continuous Fiber Reinforcement -

Print Bed

Precision Machined Aluminum

System Details

The FX20 is the largest and most precise machine Markforged has ever produced. It features an 80L heated build chamber and massive precision ground vacuum bed with reusable print sheets. The motion control system offers closed loop control through precision linear encoders, and is tuned to move the 3kg print head rapidly and accurately. FX20’s turbo mode builds parts faster than any Markforged machine, while new XL spools offer four times the material without spool changeover. The FX20 is remarkably easy to use. It features a 7 inch touchscreen from which users can control every aspect of the printer. Automated calibration and levelling reduces operator input, while a wide variety of sensors give live feedback on machine performance. A material bay contains two active XL spools and can store two more with precise moisture control.

Materials

- Onyx™

- Onyx FR™

- Onyx ESD™

- Nylon

- Carbon Fiber

- Carbon Fiber FR

- Aramid Fiber (Kevlar)

- Fiberglass

- HSHT Fiberglass

- ULTEM 9085 Filament

Metal X

The Markforged Metal X provides an end-to-end metal manufacturing solution that makes the production of metal parts much simpler than before. With the Markforged’s groundbreaking new metal 3D printing technology, Metal X can deliver metal parts overnight and that too at a fraction of cost. Additionally, as compared to alternative metal 3D printers in the market today, Markforged Metal X is 10x less expensive and up to a 100x less than traditional metal fabrication technologies like machining or casting.

Hardware

-

Printing Process

Metal FFF -

Z Layer Resolution

50 μm - 125 μm (Post-Sinter) -

Printing Media

Bound Powder Filament -

Power

100–120 / 200-240 VAC (12A / 6A), IEC 60320 type C20

-

Internal Part Geometry

Closed Cell Infill (Triangular) or Solid Parts -

Print Bed

Heated, Auto Leveling, Replaceable Print Sheets -

Build Volume

300 x 220 x 180 mm (11.8 x 8.7 x 7.1 in) -

Print System

Two nozzles — Metal material and release material

System Details

The Metal X 3D printer is based on the Markforged’s renowned composite 3D printing technology, but instead of using composite material, the printer uses the metal powder that is bound in a plastic matrix. It reduces the safety risks associated with other forms of metal 3D printing. For 3D printing metal parts, Markforged Metal X uses groundbreaking Atomic Diffusion Additive Manufacturing (ADAM) technology that allows the user to create cost-effective and high-quality metal parts. This process involves using a bound metal powder rod enclosed inside a plastic filament. Just like the other 3D printing technologies like FDM, the metal parts are built up layer by layer. This metal 3D printing process helps create light parts that don’t sacrifice on the part strength. Currently, the Metal X is able to print 17-4 Stainless Steel, Inconel 625, H13 Tool Steel, A2 Tool Steel, D2 Tool Steel and Copper. There are other materials such as 316 Stainless Steel and Titanium that is under testing and will be released in the near future.

Materials

- 17-4 PH Stainless Steel

- Copper

- H13 Tool Steel

- Iconel 625

- A2 and D2 Tool Steel

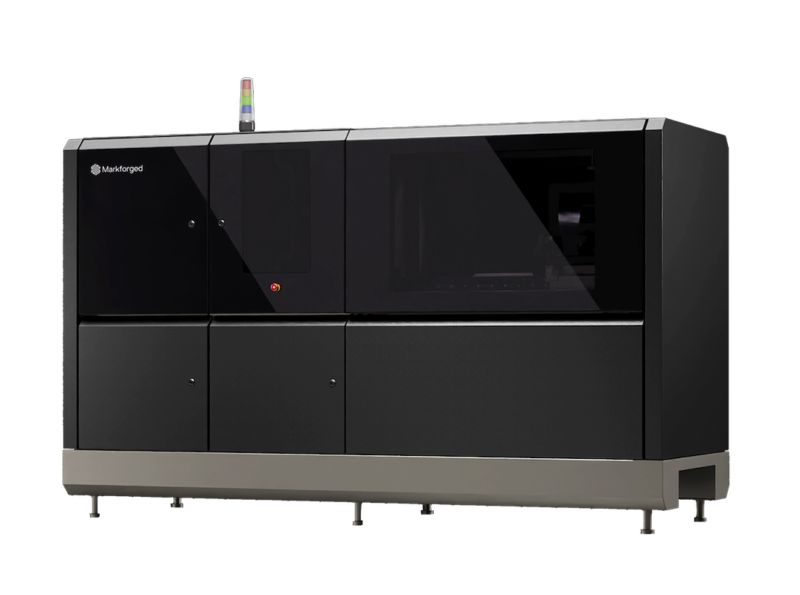

PX100

PX100, previously offered as the DMP Pro system, is a powerful new industrial metal 3D printer that delivers speed, precision, and adaptability, making metal additive manufacturing the productive choice for more and more applications. The PX100 is a game changer in binder jetting technology, enabling series production of everything from industrial components to medical and consumer goods.

Hardware

-

Printing System

Page-wide print system with 70,400 ink nozzles -

Machine Footprint

2700 x 1000 x1700 mm (L x W x H) -

Build Volume

250 × 217 × 70 mm or

250 × 217 × 186 mm (L x W x H) -

Material Deposition

Recoating with powder applicator

-

Weight

2000 kg -

Typical Productivity

500 – 1,000 cm3 /h -

Accuracy

Static accuracy better than 1µm -

Power Consumption

3.5 kW (average) -

Material Recirculation

Yes, with no degradation

System Details

PX100 has been built to deliver an optimal combination of speed and precision. At its heart is a printhead incorporating an extraordinary 70,400 print nozzles that eject 2 pL droplets at 15.5 kHz. With the level of detail that the PX100 delivers, you can create metal objects with complex geometrical structures, intricate internal detailing, and integrated that are impractical – or even impossible – to produce with traditional methods. It is a technological advance industrial metal 3D printer that ensures high-quality, high-volume production in countless applications.

Materials

- Ti6Al4V

- 316L Stainless Steel

- 17-4PH Stainless Steel

- D2 Tool Steel

- H13 Tool Steel

- 4140 Steel

- Alloy 625

- Alloy 718

- Alloy 247

- Copper