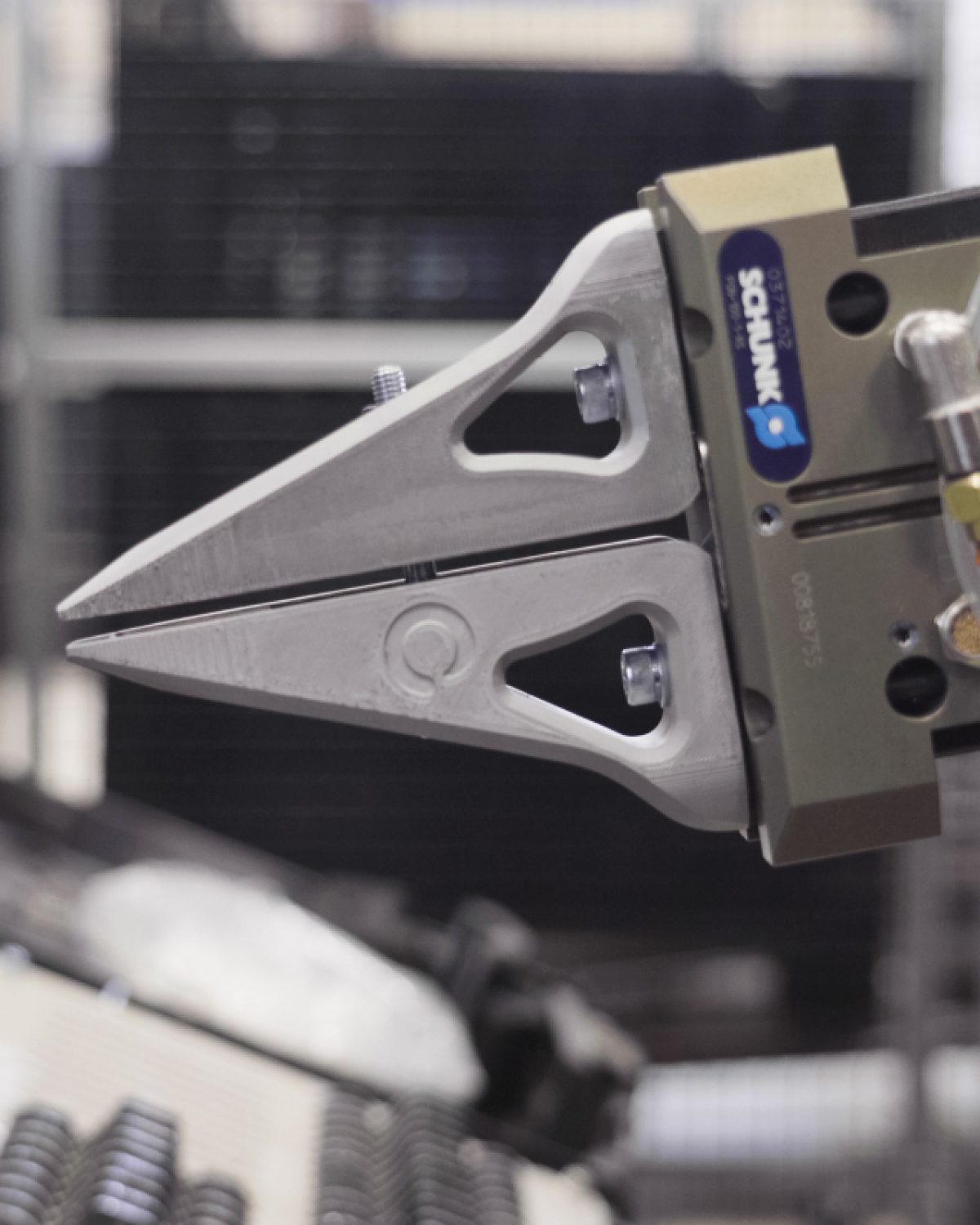

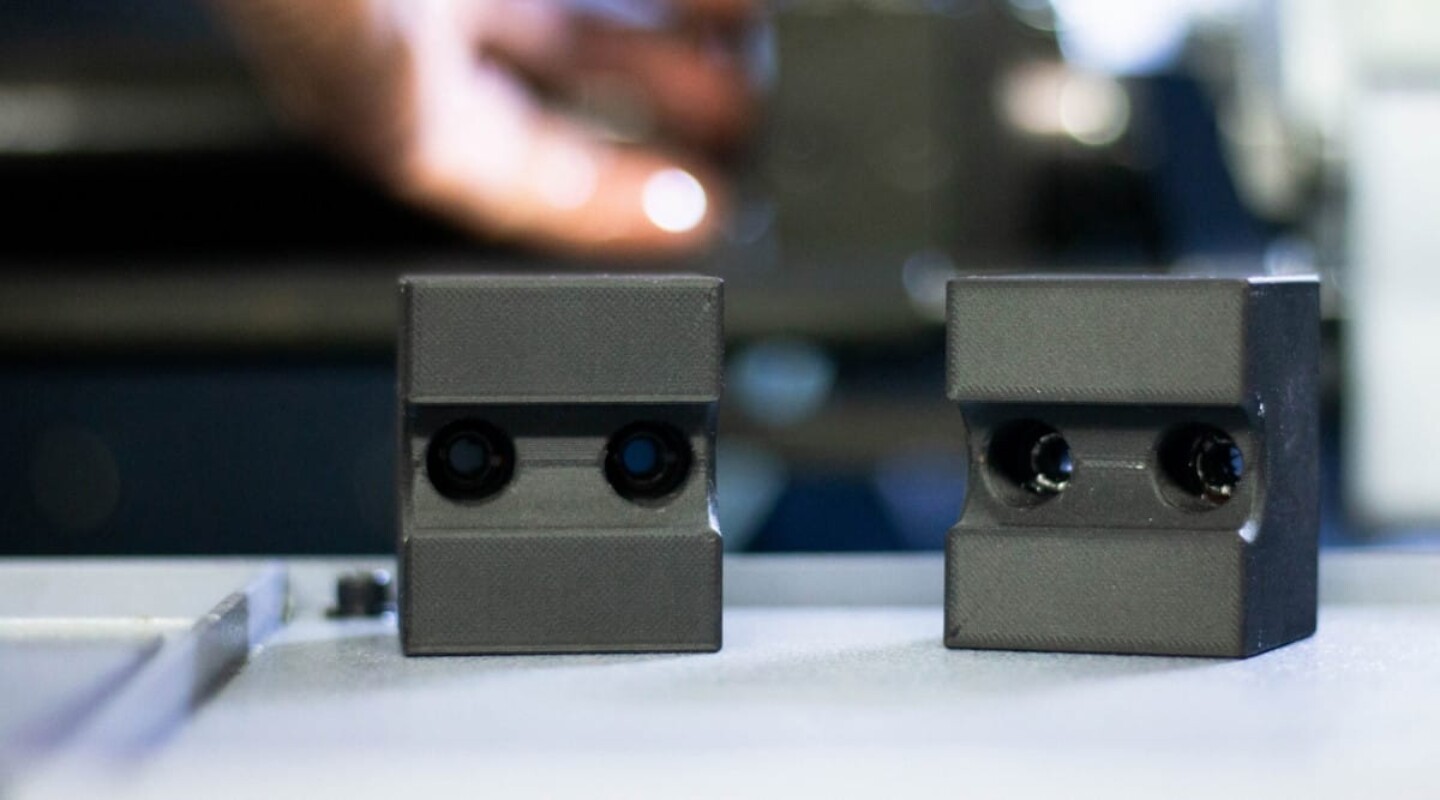

17-4 PH Stainless Steel

17-4 PH Stainless Steel is a multipurpose steel used for industrial applications. Heat-treatable to 36 HRC and possessing 95% wrought strength, Markforged 17-4 PH enables you to print high-strength, robust metal parts for a wide variety of applications.

Supported Printers

- Metal X System

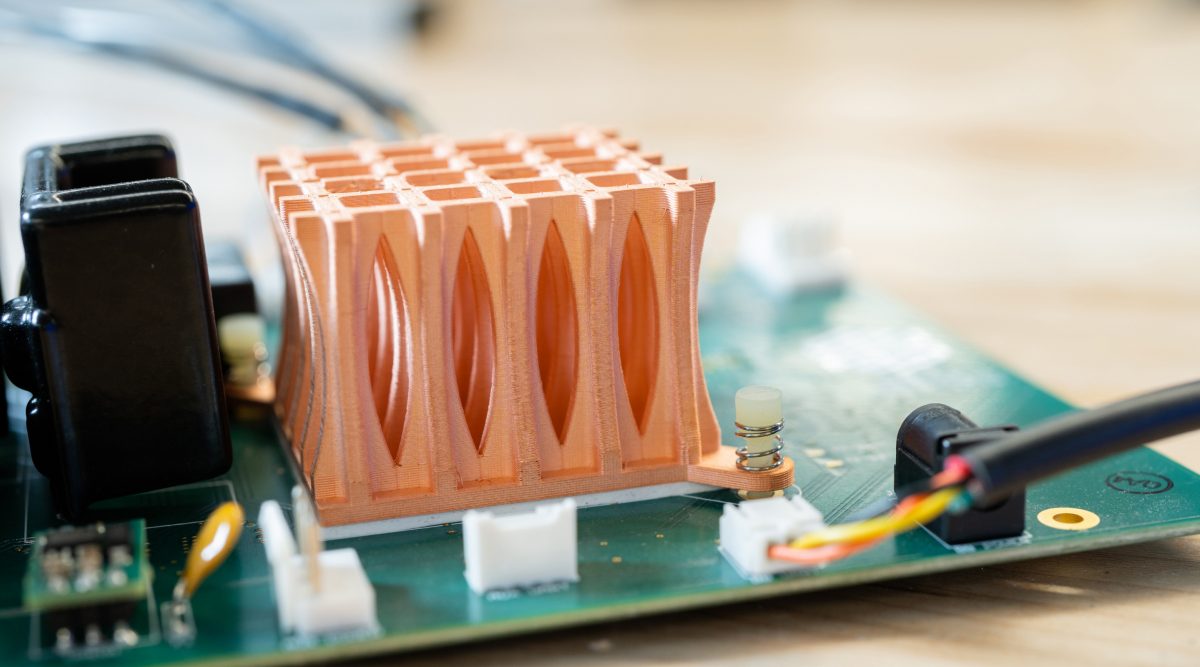

Copper

Unparalleled in its ability to conduct both heat and electricity, pure Copper is a unique metal to 3D print. Markforged Copper possesses better conductivity characteristics than alloyed copper that can be printed on DMLS machines. Unlike conventional fabrication processes which are extremely labor intensive and expensive, Markforged Copper is extremely simple to 3D print.

Supported Printers

- Metal X System

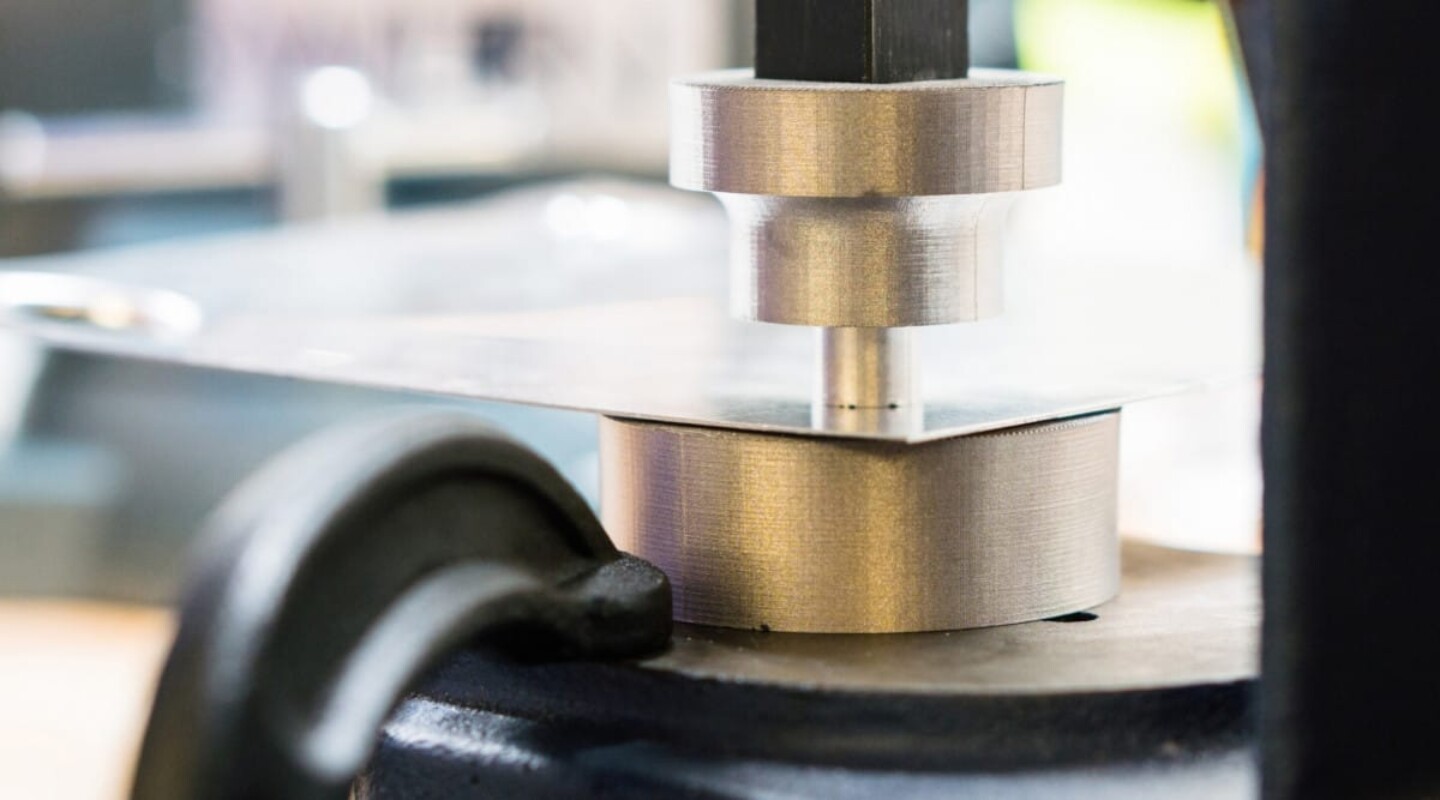

Inconel 625

Inconel 625 is a nickel-chromium based superalloy that is extremely resistant to corrosion and strong at high temperatures. It’s easy to print, enabling you to fabricate functional prototypes and end-use parts designed for harsh environments. Markforged Inconel 625 meets chemical requirements of ASTM B443 and maintains a UTS of 500 MPa at 600 ºC.

Supported Printers

- Metal X System

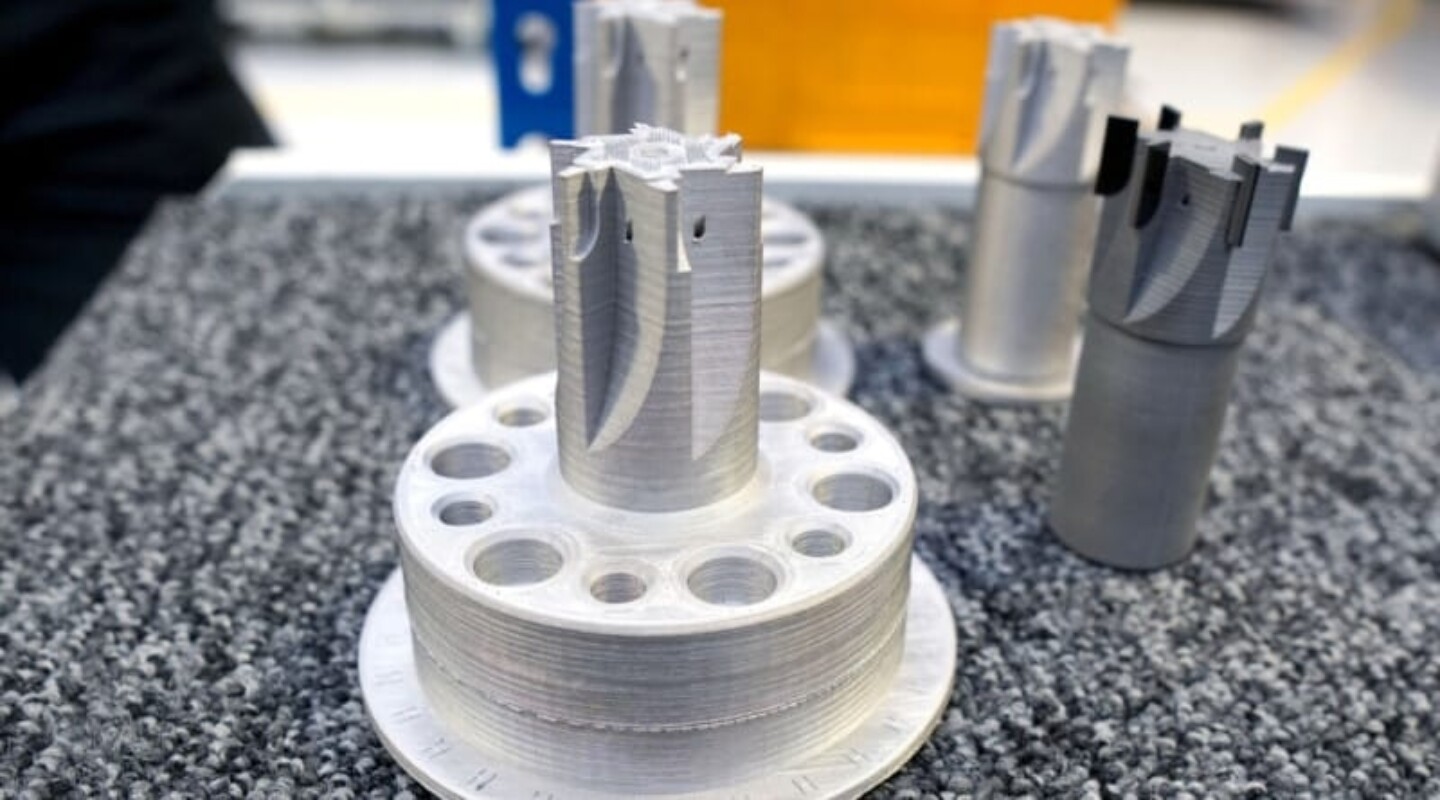

H13 Tool Steel

Harder than 17-4 PH Stainless Steel and capable of maintaining material properties at high temperatures, H13 tool steel is an extremely versatile material to work with. Markforged H13 can be heat treated to 45 HRC with a UTS of 1500 MPa, and is used by Markforged customers for tool bodies, brazing fixtures, and other parts where hardness or heat resistance are required.

Supported Printers

- Metal X System

A2 and D2 Tool Steel

A2 and D2 are cold work tool steels defined by their extremely high hardness after heat treatment. A2 tool steel is often regarded as a “universal” cold work steel, offering a combination of good wear resistance and high toughness. D2 tool steel is harder and more wear-resistant, but less tough. Both can be used for cutting and forming tools, or other applications where high hardness are valued.

Supported Printers

- Metal X System

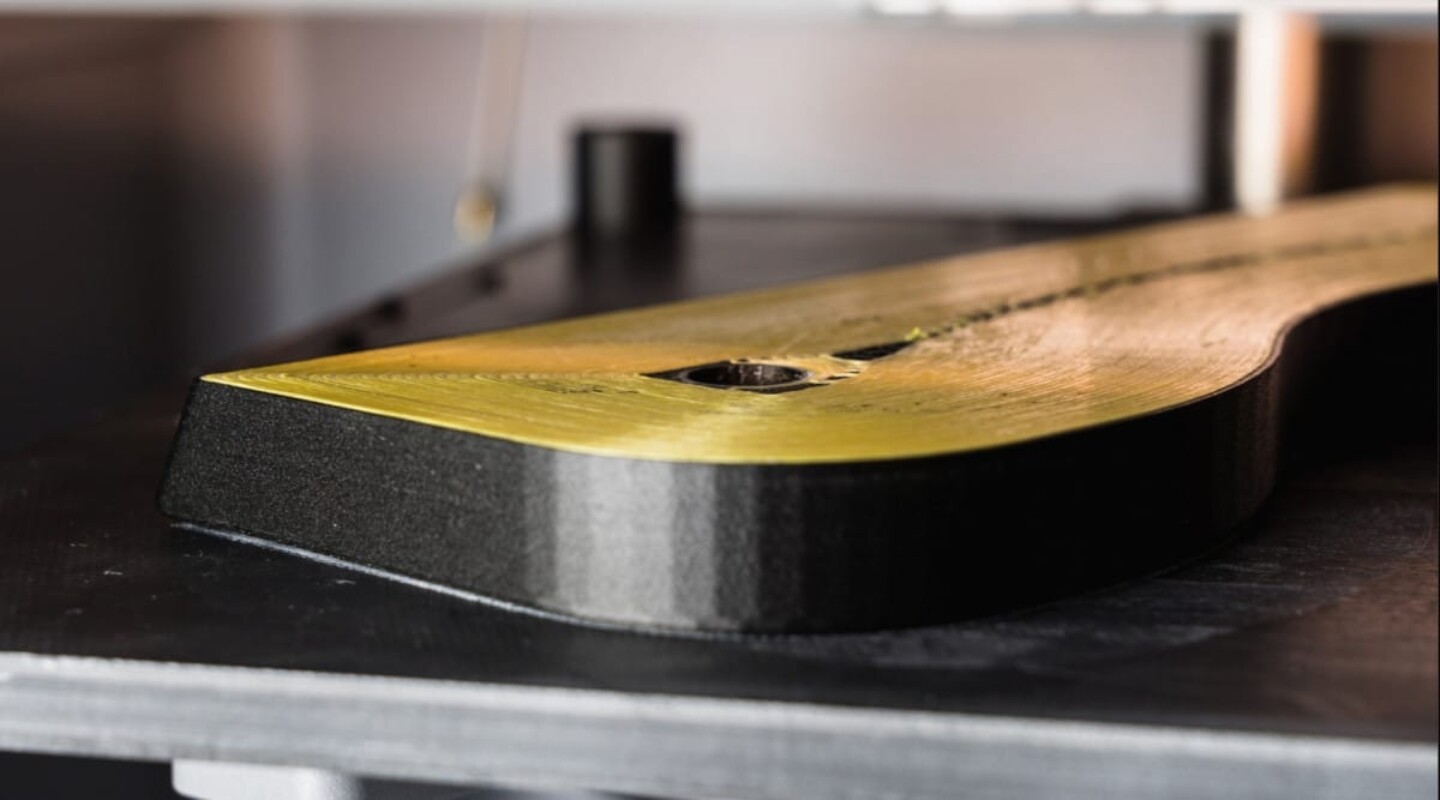

Onyx

Onyx — our flagship Composite Base material — is a micro carbon fiber filled nylon that yields accurate parts with impeccable surface finish. Few materials have the versatility of Onyx; it offers high strength, toughness, and chemical resistance when printed alone, and can be reinforced with Continuous Fibers to yield aluminum-strength parts. Today, there are more than a million Onyx parts in the field transforming manufacturing.

Supported Printers

- FX20

- X7

- X3

- Mark Two

- Onyx Pro

Onyx FR

Onyx FR is a flame-resistant variant of Onyx designed for use in applications where parts must be non-flammable. The material earned a UL Blue Card, and is considered V-0 (self extinguishing) at thicknesses greater than or equal to 3mm. It can be reinforced with any Continuous Fiber and is compatible with industrial composite 3D printers.

Supported Printers

- FX20

- X7

- X3

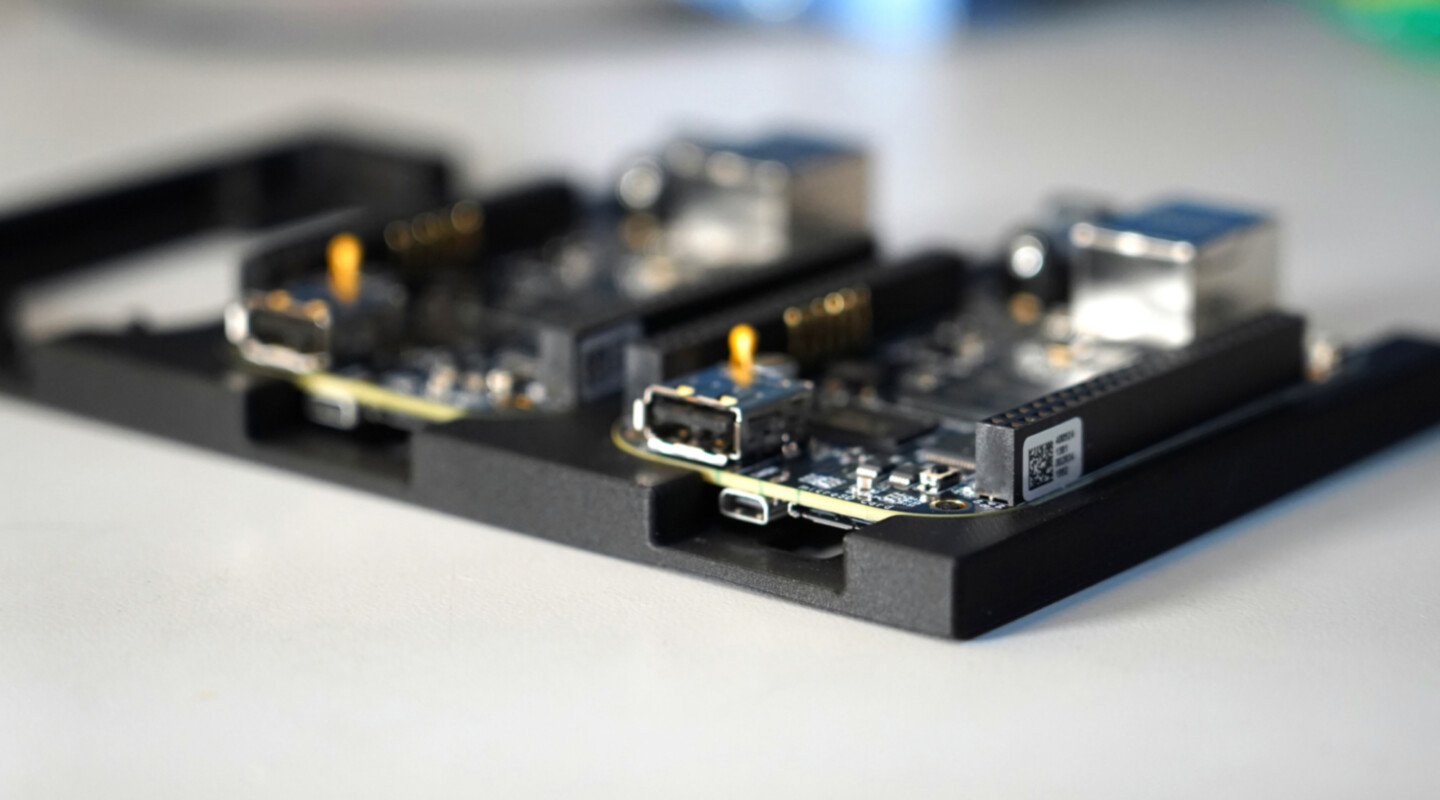

Onyx ESD

Onyx ESD is the most advanced polymer we’ve ever developed. It’s precision-engineered to possess an extremely tight range of surface resistance — meeting ESD-safe requirements of the most stringent manufacturers — while offering the same industry leading benefits that Onyx offers. In fact, it’s actually stronger and stiffer than Onyx with similarly impeccable surface finish, making it the go-to material for advanced applications.

Supported Printers

- FX20

- X7

- X3

Nylon

Nylon is an unfilled thermoplastic. It’s a non-abrasive material that is great for ergonomic surfaces and workholding for pieces that are easily marred. It can be painted or dyed.

Supported Printers

- FX20

- X7

- X3

- Mark Two

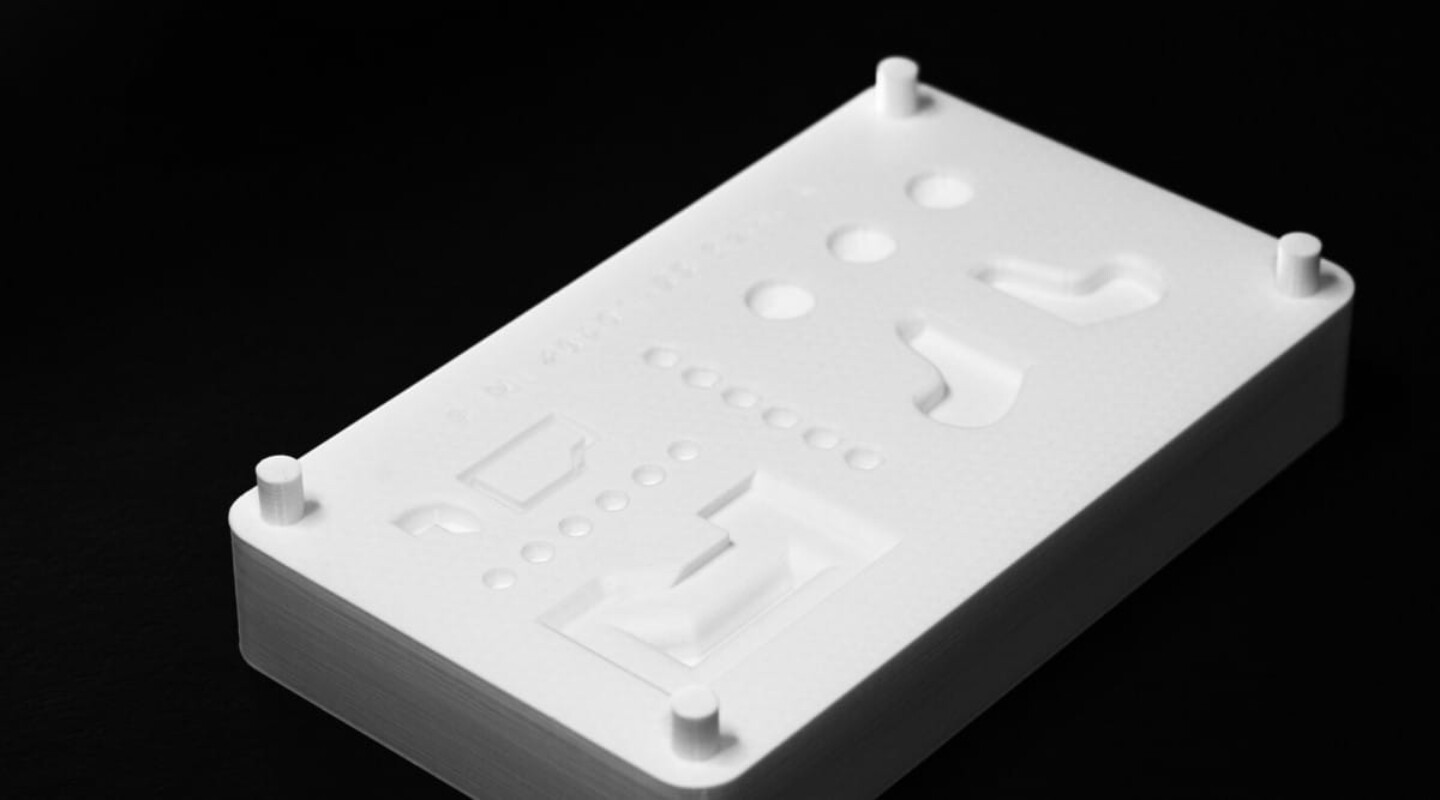

Precise PLA

Precise PLA is our easy-to-print plastic for precision concept modeling and validation. Based on the most common 3D printing prototyping material, Precise PLA 3D prints without warping and comes in a variety of colors. Best of all, it’s affordable. So you can use as much as you need to fine-tune your designs before implementation.

Supported Printers

- X7

- X3

- Mark Two

- Onyx Pro

Smooth TPU 95A

Smooth TPU 95A is a rubber-like material that when used with Markforged composite printers offers product developers and manufacturers the ability to create flexible, impact-absorbent parts on demand.

Supported Printers

- X7

- X3

- Mark Two

- Onyx Pro

ULTEM™ 9085 Filament

ULTEM™ 9085 Filament is Markforged’s first high temperature printing polymer. It’s an extremely durable thermoplastic that exhibits excellent flame, smoke, and toxicity (FST) characteristics. Usable in production aerospace applications, ULTEM™ Filament brings Markforged’s CFR technology to a new realm of parts.

Supported Printers

- FX20

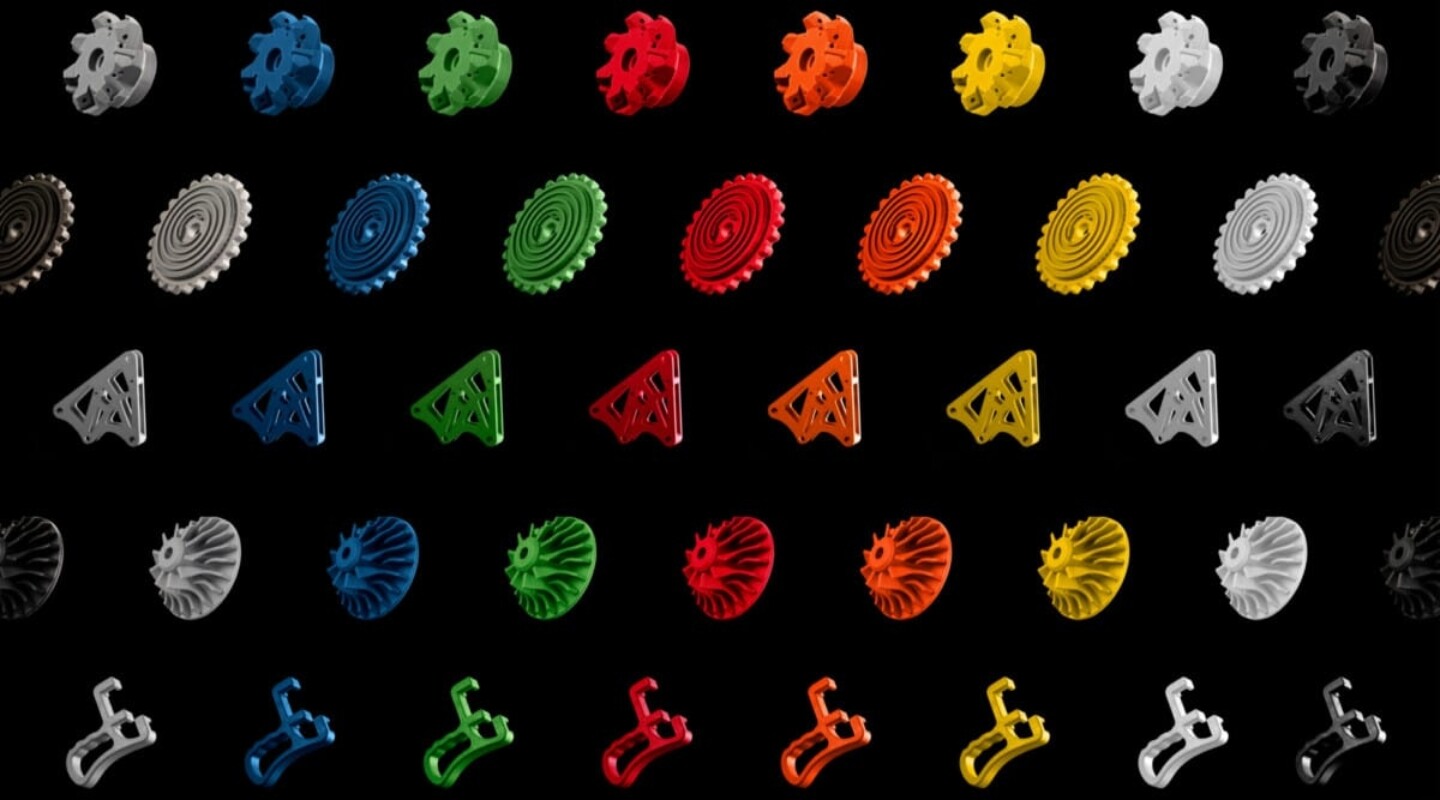

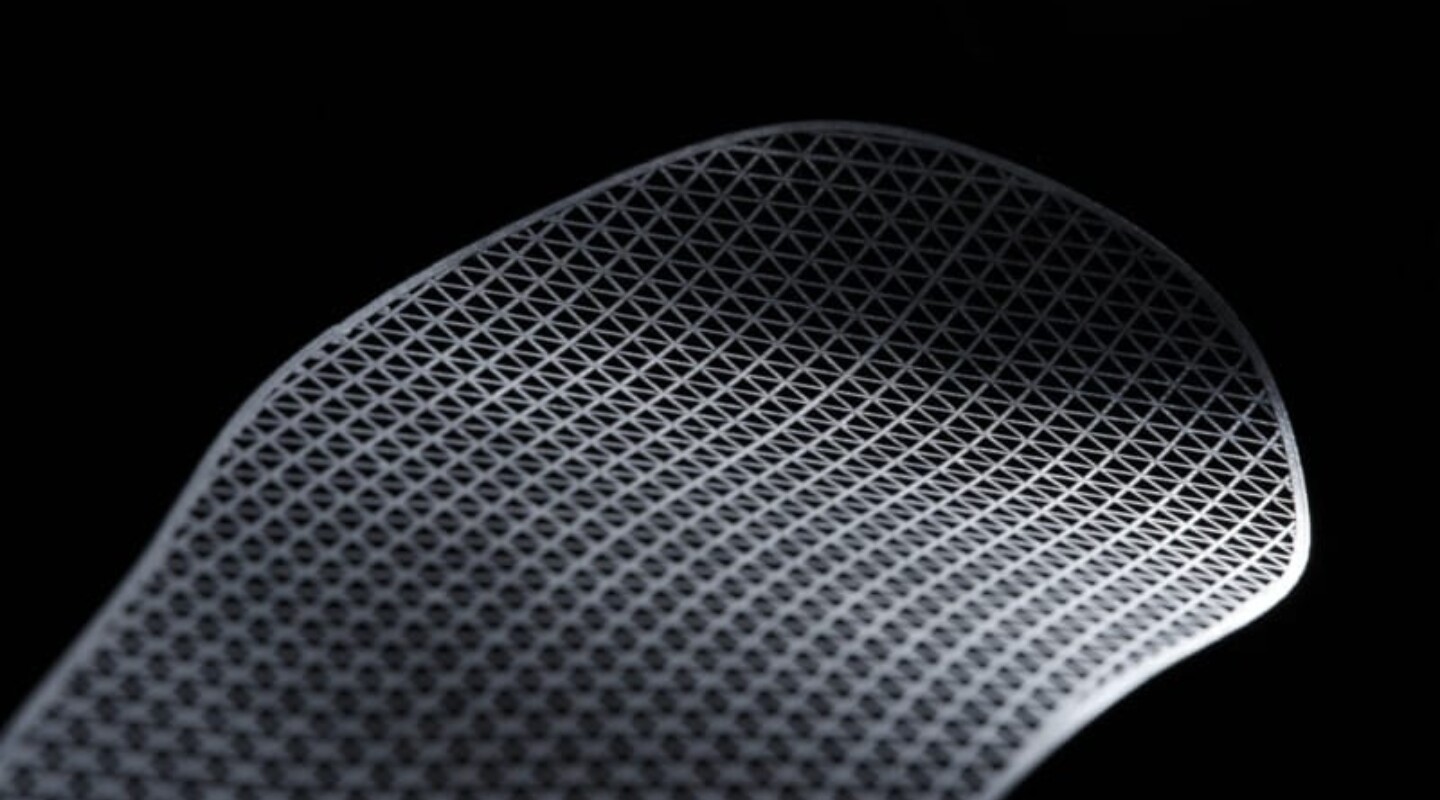

Carbon Fiber

Carbon Fiber is Markforged’s unique, ultra-high-strength Continuous Fiber — when laid into a Composite Base material like Onyx, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff and strong, and can be automatically laid down in a wide variety of geometries by Markforged 3D printers.

Supported Printers

- FX20

- X7

- Mark Two

Carbon Fiber FR

Carbon Fiber FR is a flame-retardant variant of Markforged’s unique, ultra-high-strength Continuous Carbon Fiber — when used to reinforce a Composite Base material like Onyx FR, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff and strong, and can be precisely laid down in a wide variety of geometries.

Supported Printers

- FX20

- X7

Aramid Fiber (Kevlar®)

Aramid Fiber is a Kevlar® based, specialized Continuous Fiber known for its energy absorption and extreme toughness. When laid into Onyx or another Composite Base material, it yields extremely impact-resistant parts that are nearly immune to catastrophic failure (fracture).

Supported Printers

- FX20

- X7

- Mark Two

Fiberglass

Fiberglass is Markforged’s entry-level Continuous Fiber —a material capable of yielding parts 10x stronger than ABS when laid into a Composite Base material like Onyx. Fiberglass is the flagship material of the Onyx Pro and X5 and printable on the Mark Two and X7, providing a more affordable alternative to Carbon Fiber.

Supported Printers

- FX20

- X7

- Mark Two

- Onyx Pro

HSHT Fiberglass

High Strength High Temperature (HSHT) Fiberglass is defined by two characteristics: high strength (nearly equal to 6061-T6 Aluminum) and strength in high temperatures. Though not as stiff as Continuous Carbon Fiber, Onyx parts reinforced with HSHT are strong at both low and high temperatures.

Supported Printers

- FX20

- X7

- Mark Two